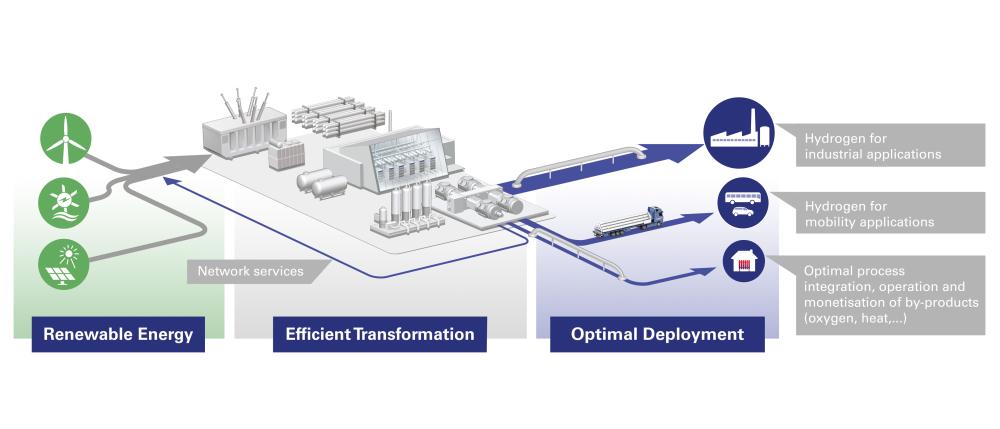

To make the production and use of clean hydrogen as economical as possible, the optimized use of electrolysis is crucial. Messer has developed the "H2 On Site Concept" precisely for this purpose.

Advantages of Messer's "H2 On Site Concept":

- Precisely tailored integration of water electrolysis into existing processes

- Efficient design of the power supply for electrolysis

- Profitable marketing of the hydrogen (not required by the plant itself) and the electrolysis by-products oxygen (O2) and thermal energy

- Development of the market for emission-free mobility

- Planning, financing, construction and operation of electrolysis-based hydrogen production plants by Messer, in line with the "Build Own Operate" (BOO) business model

An electrolysis-based hydrogen production plant therefore not only produces green hydrogen for customers on site. It also produces oxygen and heat, and can be used for grid-serving services. In the Tarragona Chemical Park, Messer Ibérica operates a pipeline network for oxygen in which this by-product of electrolysis is already being used.

For our H2 On Site Concept, we have strong partners, such as Siemens Energy, for electrolysis-based hydrogen production plants in the range of <1 to 50 megawatts. This enables us to implement demand-based solutions for hydrogen production in industrial applications such as petrochemicals, chemicals, food and steel, as well as in mobility applications such as buses, trucks or trains.